Carwash equipment daily maintenance checklist

BASIC DAILY WASH EQUIPMENT MAINTENANCE

Ensuring the upkeep of car wash equipment is perhaps one of the simplest yet often overlooked methods to extend the lifespan of your car wash system and cut costs. By implementing regular training and fostering a culture of consistent maintenance, you can minimize downtime and maximize uptime. This approach can result in significant savings by preventing equipment repairs, vehicle incidents, and premature wear. Check out this list as a starter to help develop a maintenance routine for your wash to keep things cleaning.

First and foremost, to be a successful carwash owner and operator, it is important to think proactively, not reactively, in terms of operating a profitable business. Proactive thinking reduces the likelihood of unexpected situations, such as wash shutdowns, and ensures that repeat customers can continue to depend on your reliable and efficient service.

DAILY ROUTINE

STEP ONE - GHOST WASH & FIRST WASH

- Run a test wash (also called a ghost wash or wet down) without a vehicle present at least 30 minutes before your carwash opens.

- Perform a test wash with a vehicle present and walk through with the vehicle to perform a visual inspection.

- Make note of any suspicious equipment that can be further analyzed that evening or during weekly preventative maintenance.

STEP TWO - GENERAL SITE AND BUILDING CLEAN-UP/ INSPECTION

- Clean the walls.

- Hose the floor.

- Check drains and clean them.

- Store tools and equipment (like hoses).

- Check in-bay light fixtures and exterior lights. Are you showing off your nice facility?

- Check entrance and exit signs. Are they clear and tatter-free?

- Check equipment for air leaks.

- Check for water leaks.

- Check extra service light bars.

- Check and clean entrance mirrors.

- Check heaters and the thermostat.

STEP THREE - TECHNOLOGY & PAYSTATIONS

- Check WIFI and make sure building technology is online.

- Check the lights.

- Check the viewing screen.

- Check the keypad.

- Check the voice module.

- Check the intercom system.

- Check that the validator working.

- Check that the credit card reader in working order and hasn't been tampered with.

- Make sure reader is free of obstructions.

- Make sure back-up payment system (like Stripe, Paypal, SquareUp and Ipad) is charged, online, and in working order.

- Check website payment systems and make sure membership portals are active and online.

STEP FOUR - GUIDE RAILS, CHAINS & CONVEYORS

- Check the Chains/Conveyor

- Check the correlator.

- Check the entry and exit dolly gates.

- Ensure clear of obstructions.

STEP FIVE - SOAKERS & FOAMING ARCHES

- Check all hoses and fittings for leaks.

- Check for plugged nozzles.

- Check for complete coverage.

- Check the water flow and direction.

- Check for plugged nozzles.

- Check for complete coverage.

- Check the detergent levels.

- Check for water and chemical leaks.

- Check for air leaks.

- Inspect the foam generators.

STEP SIX - WHEEL CLEANER

- Hose down cloth.

- Check for damage.

- Check for plugged nozzles.

- Check water lines.

- Check for oil leaks.

- Inspect mounting bolts.

- Check the tension spring.

STEP SEVEN - FRICTION CURTAINS

- Hose down the cloth.

- Check for damage.

- Check for plugged nozzles.

- Check water lines.

- Check for hydraulic oil leaks.

- Inspect mounting bolts.

- Check for loose clips.

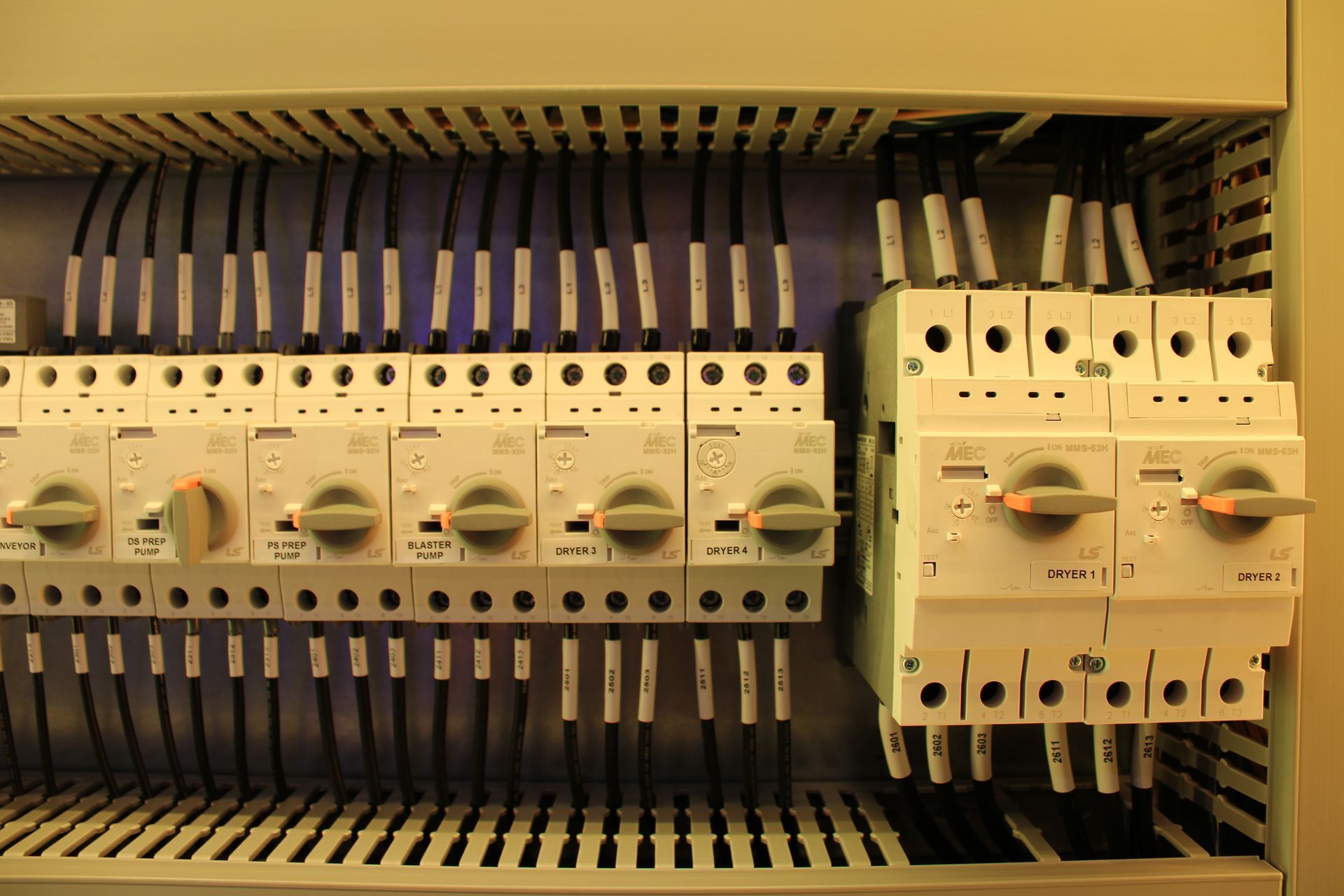

STEP EIGHT - BLOWERS

- Check all mounting brackets and bolts.

- Check the top blower oscillation.

STEP NINE - END OF DAY/ CLOSING ROUTINE

As the last few cars of the day enter the car wash, walk through with the vehicle and stay alert for any issues. Address any repairs or parts orders as necessary. Engage your employees in this procedure. The more you involve them in regular checks, the more they will learn about the car wash and be better prepared to handle equipment issues in the future. Finally, when you complete your day, carrying out a closing preventative maintenance routine such as the one suggested will set you up for a successful operation the following day.

- Check and transfer detergents.

- Inspect barrels and tanks.

- Monitor detergent use. Has consumption spiked, or has use decreased not related to wash volume?

- Check for worn nozzles, open check valves and order parts, if needed.

- Check the water softener salt levels and fill, if needed.

- Check equipment for damage, and replace parts or order new ones, if needed.

- Start cleaning the site a few hours before you are set to close, including:

- Taking out the trash

- Emptying vacuums

- Cleaning the lobby (sweeping or vacuuming and cleaning the beverage/snack area)

- Cleaning bathrooms and windows.

- Turn off and drain air compressors.

- Inspect and clean filters and strainers.

- Turn off anything that isn’t necessary.

- Turn on your security system